This study aims to statistically analyze the variation in adherence to technical specification criteria in the quality assurance and quality control of a tailings pile. QA/QC is the process that ensures compliance with technical design specifications throughout construction, thereby guaranteeing the quality and conformity of the work. A case study was carried out with real data from the construction of a tailings pile, where the release control of the compacted layers is performed based on the void index (e). In this context, to satisfy the technical specifications, the evaluated geotechnical parameter for the layer being studied must be less than 0.64.

The field of statistics is widely explored and utilized in various areas of activity, both in academic and practical contexts. Historically, the behavior of materials in geotechnics has been addressed in a deterministic manner, which can result in considerable errors due to uncertainties associated with the measurement of geotechnical parameters, the execution of tests, and the natural distribution of soils. The application of statistical analyses in mining geotechnics has seen increased recognition and importance in recent years; however, it still reflects a constrained approach.

Database

As previously stated, the database consists of actual data related to the disposal of a tailings pile. The analysis included 1,030 samples with no missing data, of which 8 points surpassed the technical design specification. As the release parameter of the layers under consideration is the void index, the geotechnical parameters Specific Grain Mass ( rs ) and Apparent Specific Mass in situ (rd) will also be analyzed, since the void index is obtained analytically from the relationship between these, according to Equation 1.

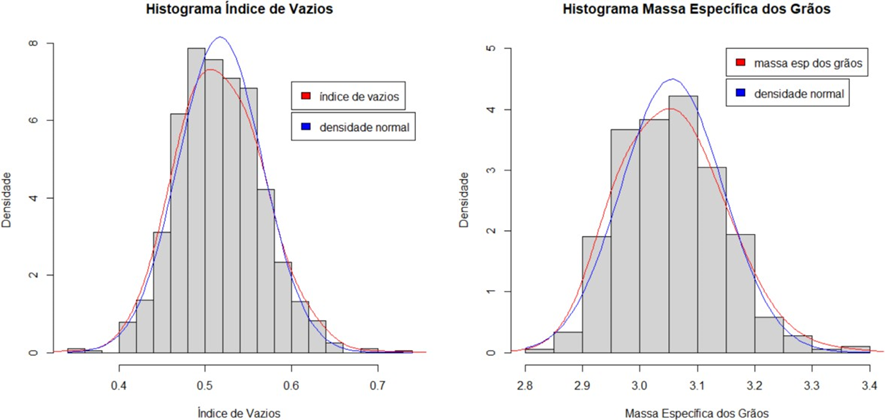

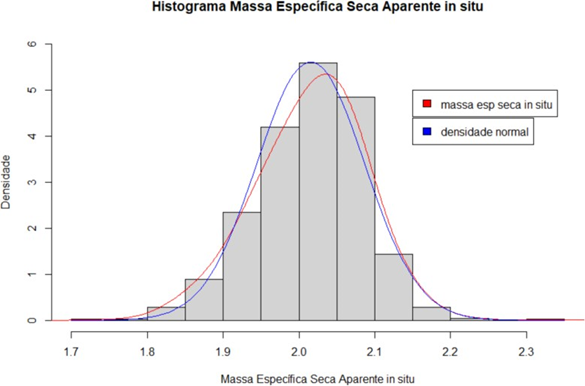

An exploratory analysis of the data will be presented below, in order to understand the behavior and the relationship between the studied geotechnical parameters. Figure 1 displays the histograms for Void Index, Grain Specific Mass, and Apparent Dry Specific Mass in situ.

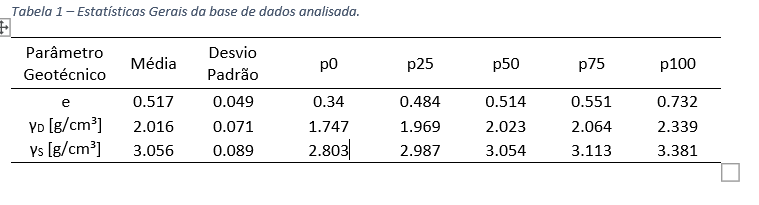

Observations from Figure 1 show that the geotechnical parameters analyzed do not present a perfectly normal distribution, and it is not possible to apply linear models to analyze their behavior and predictions. Table 1 below presents the general statistics of the data, where the symbols from p0 to p100 indicate the minimum value, the first quartile, the median, the third quartile, and the maximum value, respectively.

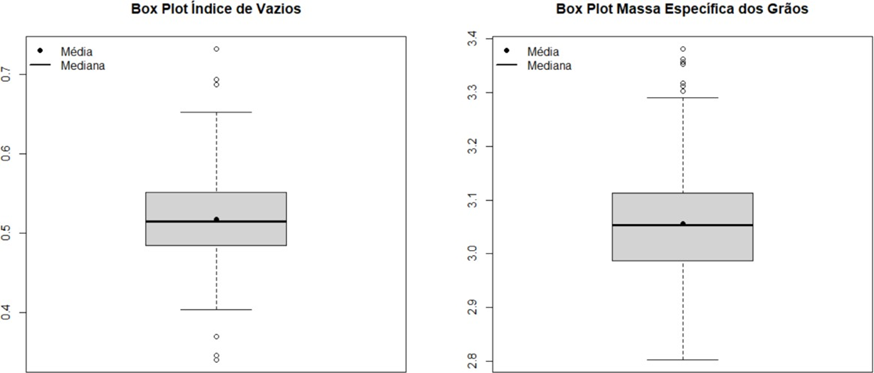

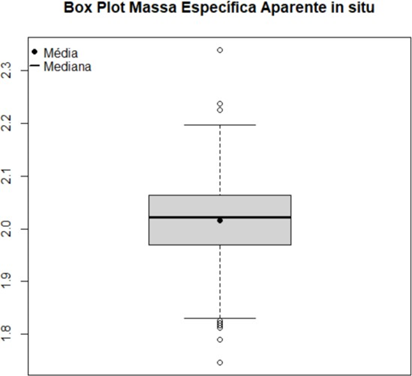

In Figure 2, the Box Plot graphs for all the analyzed geotechnical parameters are presented. The Box Plot is a statistical tool that allows graphical visualization of the general statistics, presented in Table 1, with the addition of potential outliers within each data set. According to this analysis methodology, a value is considered a potential outlier if it is 50% greater than the third quartile (p75) or 50% lower than the first quartile (p25). These points are inconsistent with the others, requiring closer attention and potential critical analysis from the professional in charge.

Observations from Figure 2 indicate that there are some potential outliers in the three geotechnical parameters under consideration. According to the histograms presented in Figure 1, the three means are very close to the three medians since the distributions are close to normal and, in accordance with Table 2, the greatest dispersion observed is in the specific mass of the grains. To evaluate the impact of outliers on adherence to the technical design specification, a comparative analysis will be conducted, assessing both analyses that incorporate these values and those that exclude them.

Results and Analysis

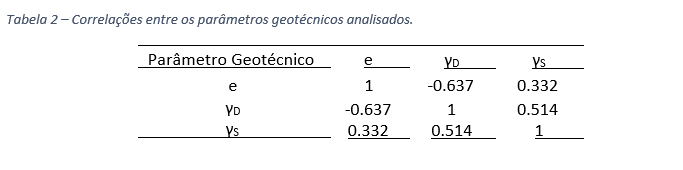

This section presents the results of analyses conducted to evaluate the influence of statistical methods on adherence to the technical specifications of a waste pile disposal project. Table 2 presents the correlations between the analyzed geotechnical parameters. Correlations can be positive (direct relationship – the higher one value, the higher the other) or negative (inverse relationship – the higher one value, the lower the other) and are more significant the closer they are to 1 or -1.

Observations from Table 2 show that the void index result presents a greater correlation with the apparent specific mass in situ, even though the specific mass of the grains presents a greater dispersion in the database, indicating that this parameter is more influenced by the field conditions than by those of the material itself. There is also a significant correlation between γD and γS, although it is not particularly high.

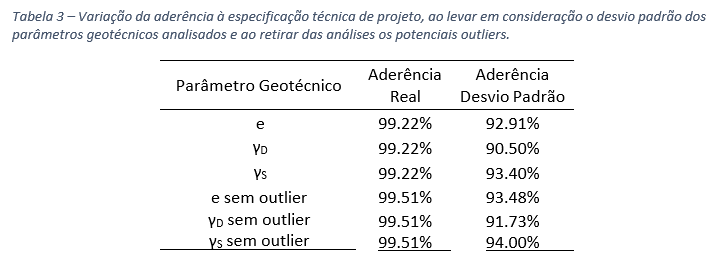

A new value for the void index will be calculated, along with an updated assessment of adherence to the technical design specification, taking into account three different scenarios: the standard deviation of the specific mass of the grains, the apparent dry specific mass in situ, and the void index itself. Next, the same analyses will be carried out while excluding the potential outliers shown in Figure 2. The analysis will focus exclusively on the most critical cases regarding their impact on the void index result, wherein the standard deviation of the relevant variable will be added to γS, subtracted from γD, and incorporated into the void index. The findings are summarized in Table 3.

When calculating the variation of geotechnical parameters from the historical data gathered during the project, it is important to account for uncertainties in the measurements of γS and γD. Moreover, it is crucial to indirectly factor in uncertainties related to other geotechnical parameters that could affect the analyzed values, including the degree of compaction, maximum dry specific mass, and optimum moisture content.

Another type of uncertainty that may exist in the process of constructing a tailings pile is related to the natural spatial distribution of the material along the structure.

Conclusions

In the analyses performed in this work, it was possible to verify a considerable change in adherence to the technical specification when adding/subtracting this value from the observations of each variable, especially when the uncertainty is associated with the apparent dry specific mass in situ, highlighting the influence of possible measurement uncertainties. This type of analysis is simplified for homogeneous materials, aiming to emphasize the necessity for caution and critical evaluation when approving values that are very close to those specified for the release of layers. This analysis highlights the critical role of incorporating statistical research in the construction of tailings piles and dams.

The type of study presented in this paper remains underutilized in mining geotechnics, particularly concerning tailings, and is crucial for enhancing our understanding of the behavior of these materials while contributing to the assurance of construction quality. Future research should incorporate additional geotechnical parameters into the analyses to facilitate a more comprehensive examination of the correlations among these data that govern the behavior of geotechnical materials. It is also recommended to implement various models, such as Bayesian analyses, mixture models, and machine learning techniques to further expand the application of statistical studies in geotechnics, thereby enhancing analytical possibilities, critical evaluations, and construction quality.