The importance of innovation has been gaining prominence in the mining sector, as the search for new technologies increasingly ensures the safety and compliance of constructions. Mining in Brazil has undergone significant advances over the years, especially in terms of organization and legislation. In geotechnical engineering, tailings disposal is one of the greatest challenges for the mining sector. The need for new techniques and methodologies that promote safer, more efficient, and environmentally sustainable construction is driven not only by the demand for innovation but also by societal pressures.

Careful supervision and critical analysis for decision-making throughout the entire construction process are essential to ensure the quality and accuracy of the results obtained during the execution of geotechnical tests and the whole quality assurance and quality control process. Geolabor is a geotechnical data management software under continuous development, striving for daily improvements and pioneering the implementation of various innovative methodologies in geotechnical practice.

To alert and modify the way technical design specifications are interpreted and verified in the QA/QC of piles and dam construction, this article will address a methodology already implemented in the system. This methodology, created by the Simplelab team, aims to ensure that technical design specifications are consistently met throughout the project by analyzing both test frequency and the representativeness of the data.

METHODOLOGY

The proposed methodology’s main goal is to guarantee that the tests performed across the project are representative to the frequency required by the technical design specification. One of the common criteria in the construction of piles and dams is the one that specifies the number of tests that must be performed for a given volume of compacted material.

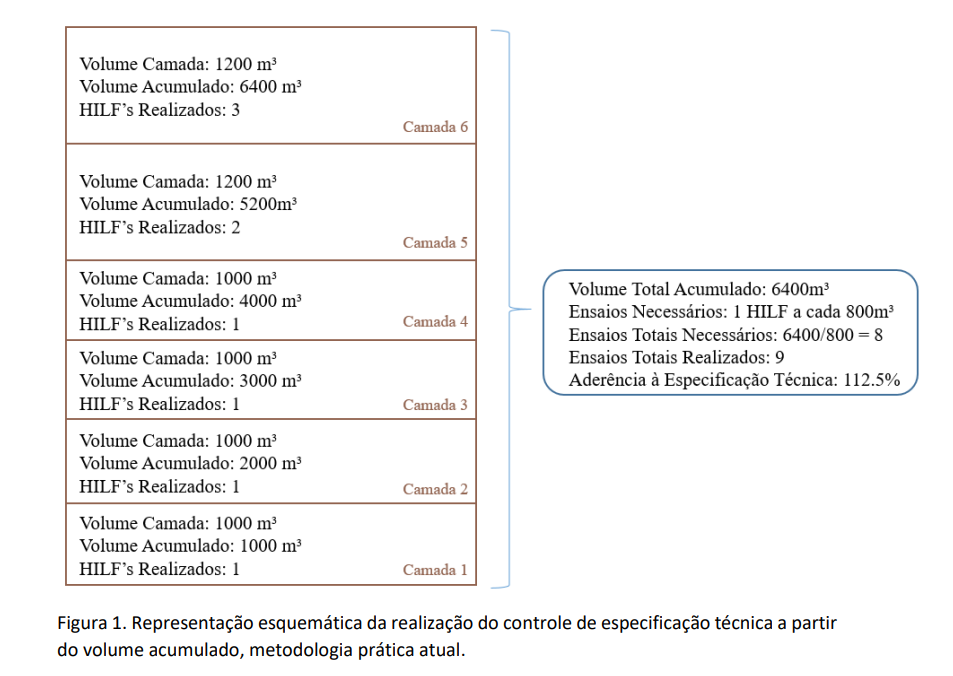

Currently, adherence to this requirement is verified through the relationship between the total number of tests conducted and the total accumulated volume in each construction area. Taking into account an area with 6 compacted layers, with a technical specification requiring 1 HILF test (compaction test using the HILF method) for every 800m³ of compacted material, in addition to requiring that at least 1 HILF test be performed per layer, Figure 1 presents a fictitious example representing the control of this supposed area, based on the current analysis, per total accumulated volume.

Figure 1 illustrates a construction site example, where 6 layers have been constructed, with a total of 6400m³ of compacted material. According to the provided technical specification, a HILF test must be performed for every 800m³ compacted. Based on the proportion between the total volume released and the volume interval needed to conduct a test, the result indicates that 8 tests are required in total. After conducting 9 tests, based on the current methodology—which considers a set of compacted layers for subsequent verification of compliance with the technical specification—the final calculated adherence is 112.5%.

When analyzing adherence to the technical specification using the current methodology, only the total amount constructed is considered, without fully analyzing the construction process itself. Following the chronological evolution of the work, upon reaching Layer 4, there is a partial accumulated volume of 4000m³. Since it is necessary to perform 1 HILF test for every 800m³, at this point at least 5 tests should have already been performed – which is not the case. Therefore, it is possible to observe that there is a range of compacted volumes that do not comply with the technical specifications of this work.

This example demonstrates that, although an excessive number of tests were performed, they do not adequately represent the entire compacted volume, even though the current control methodology reports compliance with the specified criteria. In view of the problem presented, a new way of assessing compliance with the technical specification for this type of control was developed, taking into account the entire extension and evolution of the work, to guarantee the representativeness of the tests performed throughout the construction.

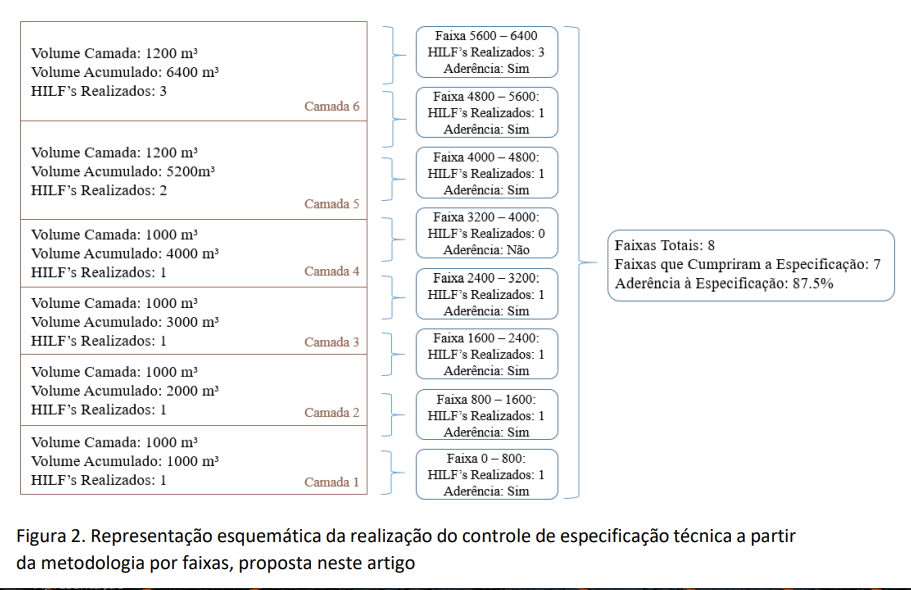

The concept of “Bands” was created to ensure this careful monitoring, so that the interval generated for each Band is the same as the volume specified per test. In other words, in the example where one HILF test is required for every 800m³, the bands for assessing adherence to the technical specification will be incremented by 800m³, represented as “0 – 800”, “800 – 1600”, and so forth. Figure 2 shows the same example as Figure 1, now assessed using the Bands methodology.

The example shown in Figure 2 has the same number of layers, compacted volumes and tests performed, with the only difference being the way of monitoring adherence to the technical design specification. Analyzing the results in Figure 2, it is possible to observe that the Bands methodology is able to identify that, upon reaching 4000m³, 5 tests had not been performed, as would be required. Each test that was performed on layers numbered 1 to 4 is housed in the first four Bands, which cover the accumulated volume from 0 to 3200m³. Using this new method of interpreting the results, automated within Geolabor, the responsible engineer would receive notification in the layer report—automatically generated by the system—that 2 HILF tests are required for Layer 4 to ensure compliance with the technical specification in its designated Band.

If a second test is not performed on Layer 4, given that the final accumulated volume of this layer has already reached the upper limit of the Band under analysis (4000m³), the system understands that it is no longer possible to perform a test within this range in order to comply with the technical specification criteria. If, instead of Layer 4 having 1000m³, it had, for example, 800m³ of compacted volume, the methodology would keep the analysis for the 3200 – 4000 Band open until the compaction of the next layer, since the maximum volume limit of the Band would not yet have been reached and a test performed on Layer 5 would still be within this range, complying with the specification. In this way, more than one layer can include the same range, just as the same layer can belong to more than one range, ensuring that the analysis will be performed based on the actual compacted volume, following the entire construction.

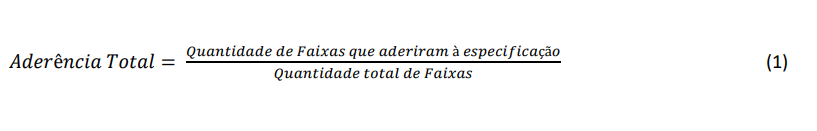

The implemented Band methodology is valid for any tests and volumes specified, and can also be extended to other types of technical design specification criteria, such as accumulated elevation or area, following the same logic used for the accumulated volume criterion. The final result presented for each construction site includes the relationship between the adhesion of each strip, the number of tests conducted beyond what was required, and the total adhesion, which is calculated according to Equation 1 below.

The integration of the methodology developed in Geolabor automates all analyses, displaying adhesion results and the relationship between the number of tests conducted and the required tests directly in the area and layer reports, respectively. The practical application of the band methodology poses no harm to any engineering sector involved in the construction of piles and dams; rather, it offers significant advantages for employees’ daily operations and in ensuring construction quality. Geolabor continues to develop and implement innovations in the geotechnical sector, striving for more rigorous and increasingly reliable QA/QC, with results that accurately reflect the reality of work.

Written by: Bianca Lacerda